Basic MIG Welding Techniques Every Beginner Has To Learn!

Ensure MIG torch is completely unravelled until setup is complete. Carefully feed in the new liner down the torch lead all the way to exit the torch neck. Fit the liner retaining nut and screw only 1/2 way down. Snip the excess liner off, about the length of the where tip holder sits past the end of the torch neck.

Simple MIG Welding Technique Flat, Horizontal, Vertical & Overhead Welding Tips & Tricks

GMAW - MIG Welding Tips Getting the Right Weld. Welding is an essential component of construction and getting the right weld is important to ensure buildings maintain their structural integrity. When it comes to gas metal arc metal welding (GMAW) - with the most common type being a fillet weld on mild steel - welders must use the right.

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Hot Rod Network

Weld a 90-degree joint. Family Handyman. Tack the joint using a magnetic jig. Start your bead by holding the gun at a 45-degree angle to the parts. For the push technique, tilt the gun 10- to 15-degrees in the direction of the weld. Be sure to remove your magnet before welding the entire joint — the heat will destroy it.

MIG Tip 1mm Welding Contact Tips for 24KD MIG Welding Brass Pack of 3

Premium laser sensors for precise 3D measurement from QuellTech GmbH. Applications from the industry with QuellTech laser measurement technology

MIG Welding Guide Learn How to MIG Weld Like a Professional Hot Rod Network

MIG Welding Tips Always read and follow the safety precautions and operational instructions in your owner's manual. 1. Keep a 1/4 to 3/8 in. stickout (electrode extending from the tip of the contact tube). Too Short: Normal: Too Long: 2. For thin metals, use a smaller diameter wire. For thicker metals, use a larger wire and a larger machine.

Mig Welding Tip Dynatex

Metal Inert Gas (MIG) welding is an arc welding process in which a solid wire electrode is continuously fed through a welding gun into a weld pool. An arc is formed between the wire electrode and base metal, melting the base material while consumable filler wire is deposited, creating the weld. At the same time, a shielding gas is fed through.

MIG Tip 0.8mm Welding Contact Tips for 15AK MIG Welding Brass Pack of 10

This article will give you 16 great tips to get you on the quickest path to success. Table of Contents show. 1. Make Sure Your Metal Is Clean. Like every welding process you'll use in your welding journey, step one should always be to make sure your material is nice and clean.

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Hot Rod Network

MIG welding tips. The material needs to be clean to get a good weld; remove any grease or oil before using abrasives. MIG welding is more tolerant of minor surface contaminants than TIG welding, but the cleaner the metal, the fewer problems you'll have. I often use sanding disks or a non-woven abrasive for cleaning rust, paint or.

The Complete MIG Welding Guide Be a King of MIG Welding!

Check out these MIG welding (GMAW) basics for beginner welders. Learn about common weld joint types, how to hold the MIG gun, stickout, travel speed and tack.

Learn MIG Welding Tips From a Pro Family Handyman

There are only 3 things that matter when learning MIG welding technique, also known as Gas Metal Arc Welding (GMAW). Watch the video where I'll break them do.

Mig Welding Techniques flat, horizontal, overhead, vertical

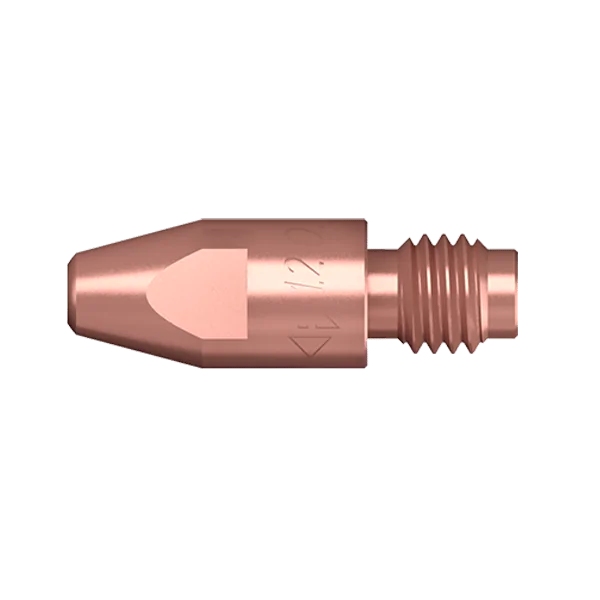

MIG welding contact tips are typically made with a chemically treated copper that transmits electrical energy through a conduit to the electrode filler wire. Another important feature of a MIG welding gun is the inert gas supply, which attaches to a gas hose for facilitating the flow of gas to the welding area through the welding torch.

MIG Tip 0.8mm Welding Contact Tips for 15AK MIG Welding Brass Pack of 5

5 Beginner's Tips for Making a Good MIG Weld. Whether you are thinking of taking a welding class, want to build your knowledge base or just need a refresher, here are 5 introductory tips for making a good MIG weld: 1. Get comfortable with the welding gun. When you are just starting out, holding a welding gun may not yet be familiar territory.

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Hot Rod Network

One of the best MIG welding tips is to reduce the voltage and amperage by around 10-15% when compared to your flat welding settings. Vertical down welding is used to reduce arc penetration when working on thin metals. This, in turn, stops excessive melt through. Worker doing a vertical position weld.

Mig Welding Tips M8 Binzel MB360 Pack Of 5 Great Quality Welder's Choice

Firmly attach the clamp to bare metal as close as possible to the arc. 3. Keep Your Stickout Short. As a general rule, keep the distance the wire sticks out from the end of the gun's contact tip to between 1/4 and 3∕8 inch. "This simple tip can have the biggest effect on your MIG welding," says Jody Collier. 4.

HOW TO GET NEAT MIG WELDS IN 3 STEPS YouTube

UNIMIG Anti Spatter Spray. 9. Vertical up. The first trick to a good vertical up weld is to make a triangle shape to keep control over the weld pool and get good fusion on both pieces all the way up. The second trick is to turn your wire speed and voltage down from the recommended settings for a down hand butt weld.

11pcs Durable MIG Welding Welder Torch Nozzles Tip Holder Contact Tips 0.040" Gas Diffuser Set

Safety precautions and tips for MIG welding: MIG welding is a powerful and precise tool that can be used to create strong, long-lasting welds. However, it is important to remember the safety risks associated with this process. The heat generated by MIG welding can cause burns and ignite fires, while sparks created during the process can also be.